What is PCHE?

What is PCHE?

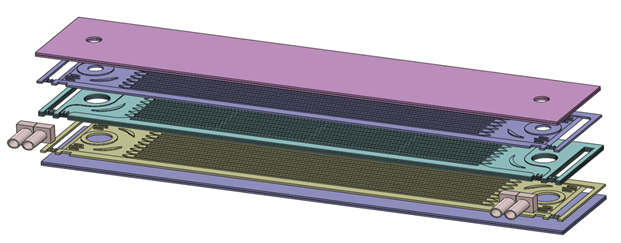

PCHE: each layer consists of etched plates, similar to the processing of electronic printed circuits

PFHE: each layer includes specially shaped fins and sealing process, and each layer is separated by thin plates

H2X: combine the above two structures. In H2X, it is formed by alternating superposition of fin plate and etching plate

Manufacturing of the DCHE:

In the vacuum environment, the weldments are closely combined and maintained at a certain temperature and pressure for a period of time. It is a welding method that makes the atoms between the contact surfaces diffuse each other to form an integral whole.

Product feature of the DCHE:

1. High heat transfer coefficient

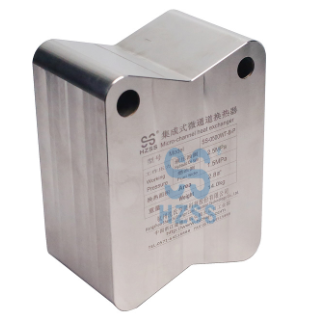

The microchannel heat exchanger for fluid heat transfer is composed of thousands of micron channels integrated by tight three-dimensional hollow combination technology. There is no contact thermal resistance, and the heat transfer coefficient can reach 5000-10000w / (m2. K).

2. Less refrigeration work and charging

Compared with the plate heat exchanger, the integrated heat exchanger with the same heat exchange capacity reduces the channel volume by 93% and the refrigerant charge is greatly reduced, which not only saves the operation cost, but also plays a positive role in reducing global warming.

3. High compactness

The compactness of the integrated microchannel heat exchanger can reach 800-2000m2 / m3, which is about 3.5 times higher than that of the Jiao plate heat exchanger. It makes the heat exchange per unit volume reach 20.0W/cm3 and the heat exchange per unit mass reach 5kW / kg. When reaching the same heat exchange capacity, it has the advantages of small volume and light weight.

4. High pressure resistance and strong corrosion resistance

The channel of the integrated microchannel heat exchanger is micron. The heat exchanger made of integrated technology has the same strength as the base metal, and the pressure resistance of the heat exchanger is up to 30MPa. The great improvement of pressure resistance makes it suitable for supercritical CO2 cycle system. The use of stainless steel makes the heat exchanger have good corrosion resistance.

|

Refrigerant

|

HFC(O)-,CO2,Others

|

|

Cycle

|

Refrigerant Cycle,Other Cycles |

|

Work Fluid

|

Water,Other Fluids

|

|

Work Flow Loop

|

Open or Closed Flow Loop

|

Filter | 100 Mesh |

Connect Pipe Material | SUS,Cu,Other |

Pressure Test | Water Pressure Test,Helium Leak TEST(<5*10-10 Pa·m3/sec) |

Burst Pressure | >30MPa |

Materialal | SUS316L |

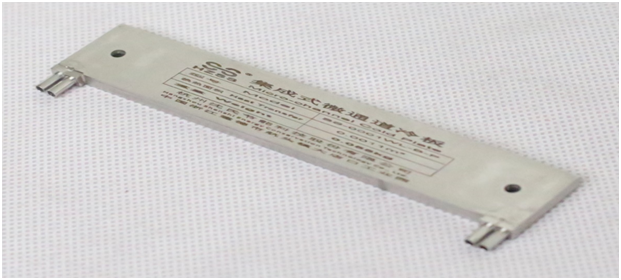

As the evaporator in the Water Puriffier:

DCHE is made of multi-layer stainless steel 316L material laminated and vacuum diffusion combined. The material is food grade, high processing precision, high heat exchange and small product volume, suitable for water purifier equipment. Mainly in the water purifier system as an evaporator.

1.The microchannel heat exchanger can be increased by 10 times compared with the storage heat exchanger;

2.Small size, especially suitable for compact, ultra-small water purifier products.

Cooler for the electronics:

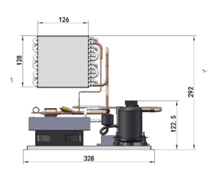

HZSS’s enclosure cooling products effectively dissipate heat from sealed electrical and electronic enclosures operating in indoor, outdoor and other types of environments. These products are applicable in diverse industries including Industrial Automation, Food Processing, Chemical, Petrochemical, Wastewater Treatment, and Telecommunications.

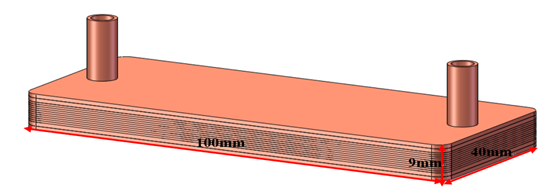

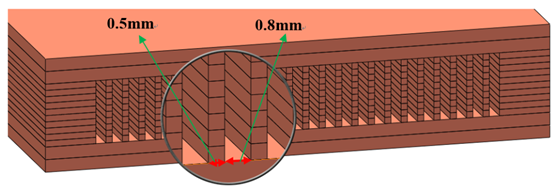

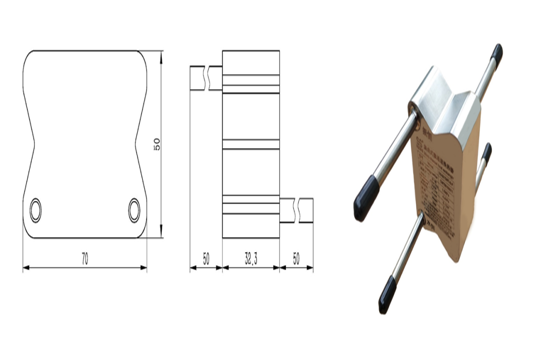

Double channel ammonia cold plate (15W) 108mm*20mm*4mm.

Large heat exchange area, high heat transfer coefficient, suitable for equipment with high local heat flow.

Conventional flow channel cold plate: general heat transfer coefficient, low cost, suitable for common equipment.

Cooling performance: can meet the cooling requirements of 200-300W/cm2 device

Advantages: diffusion bonding technology has high welding strength, diverse internal flow channels, high heat transfer area and high heat transfer coefficient.