Home / coil-in-shell heat exchanger

Coil-in-shell heat exchangerProduct Profile: HZSS's tubular heatexchanger is suitable for refrigeration (heat pump) system, which pipe runswater and shell runs refrigerant. |  |

| Model List of Coil-in-Shell Heat Exchanger | ||||||||||||||

| Model | Refrigerant | Evaporator | Condenser1 | Condenser2 | Drawing | |||||||||

| Flow rate | Capacity | Flow rate | Capacity | Flow rate | Capacity | |||||||||

| GPM | m3/h | Btu/h | kW | GPM | m3/h | Btu/h | kW | GPM | m3/h | Btu/h | kW | |||

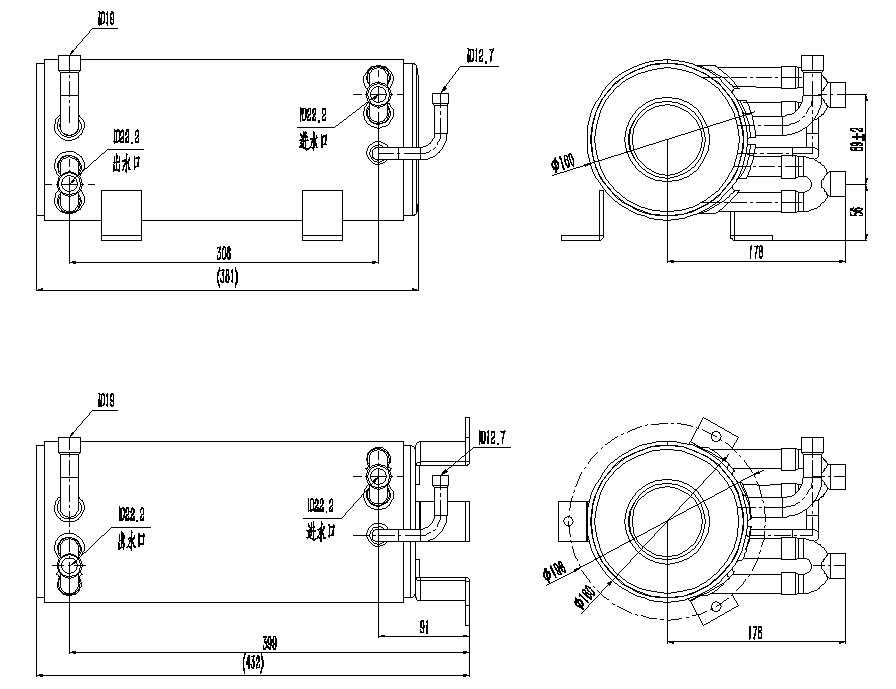

| GSS00600001 | R410A | 0.64 | 2.408 | 47800 | 14 | 0.50 | 1.892 | 37500 | 11 | 0.73 | 2.752 | 54600 | 16 | View drawing |

| GSS00600002 | R410A | 0.64 | 2.408 | 47800 | 14 | 0.50 | 1.892 | 37500 | 11 | 0.73 | 2.752 | 54600 | 16 | View drawing |

| Test condition: Evaporator, Air side temp dry/wet ball 35/24℃, water Inlet Temp 12℃,water Outlet Temp 7℃, evaporating temp 3℃Condenser1: Air side temp dry/wet ball -12/-14℃, water Inlet Temp 36℃,water Outlet Temp 41℃, condensing temp 41.5℃.Condenser2: Air side temp dry/wet ball 7/6℃, water Inlet Temp 40℃,water Outlet Temp 45℃, condensing temp 46℃. Evaporator: Air side temp dry/wet ball 95/75.2℉, water Inlet Temp 53.6℉,water Outlet Temp 44.6℉, evaporating temp 37.4℉Condenser1: Air side temp dry/wet ball 10.4/6.8℉, water Inlet Temp 96.8℉,water Outlet Temp 105.8℉, condensing temp 106.7℉.Condenser2: Air side temp dry/wet ball 44.6/42.8℉, water Inlet Temp 104℉,water Outlet Temp 113℉, condensing temp 114.8℉. | ||||||||||||||

① High thermal exchange efficicieny(1) Inner tube is high efficiency dual-healix finned copper;pipes, and heat exchange surface is 4 times that of smooth pipe. | ② Safe(1) There is no welding point on the copper pipe, so it can make sure the system work stably for a long time. |

③ Small(1) The compact structure will help save room for a system, and it is convinient to set other part of a system, so it can decline the overall dimension of all system. |

Coil-in-shell heat exchanger is widely applied for: heat pump water heater, air source heat pump water heater,central air-conditioning,water source heat pump,swimming pool device, heat recovery system, heating, drying etc.