Home / Shell and Pipe Heat Exchanger

Shell pipe heat exchangerProduct Profile: Shell and pipe heat exchanger is akind of high efficiency heat exchanger which is composed of high efficient Ω style innerpipes and plastic shell. It has the advantages of both shell & tube heatexchanger and plate heat exchanger. The shell is madeup of plastic inner tank, and foam insulation layer and steel shell. The innertubes arrangement method has been certificated as our technology inventionpatent. |  |

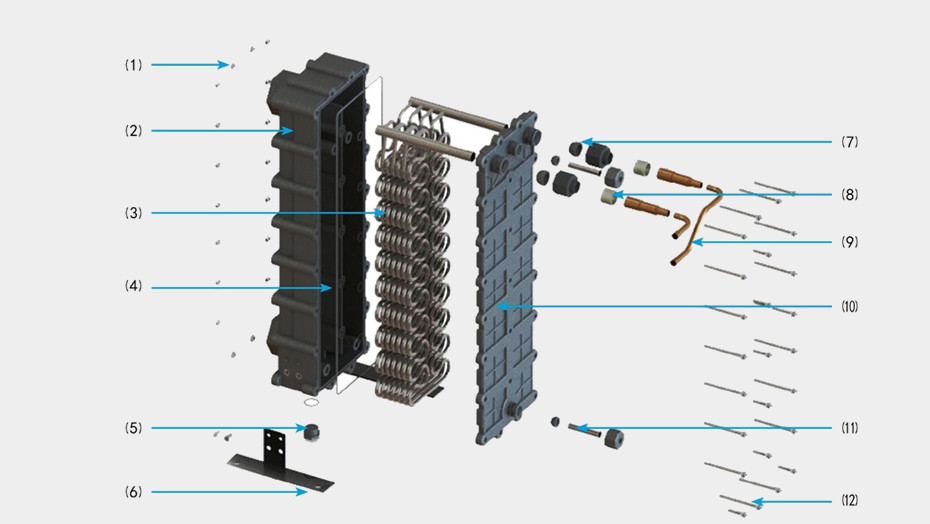

| (1)fixing nut | (2)plastic shell(PA6) | (3)heat transfer inner core | (4)water loop seal |

| (5)water outfall | (6)bracket | (7)seal ring of refrigerant loop | (8)lock ring |

| (9)connect pipe | (10)plastic cover | (11)temperature sensor point | (12)fixing bolt |

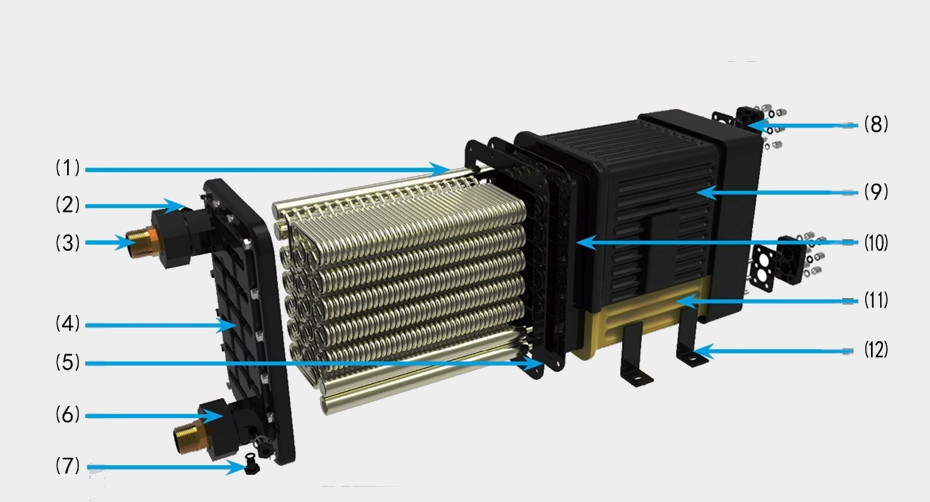

| (1)heat transfer inner core | (2)temperature sensor point | (3)metal joint | (4)steel cover |

| (5)water loop seal plate | (6)plastic cover | (7)water outfall | (8)seal ring of refrigerant loop |

| (9)steel shell | (10)plastic shell | (11)foam material | (12)bracket |

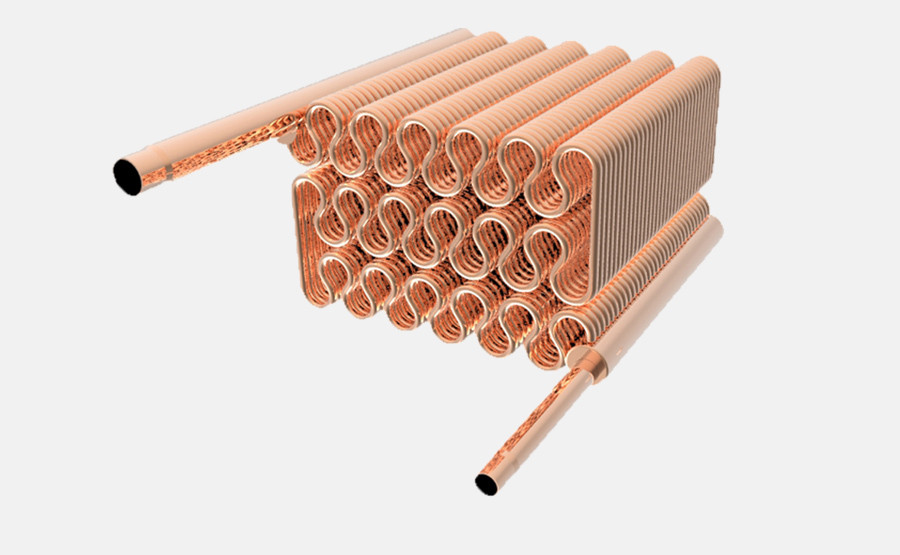

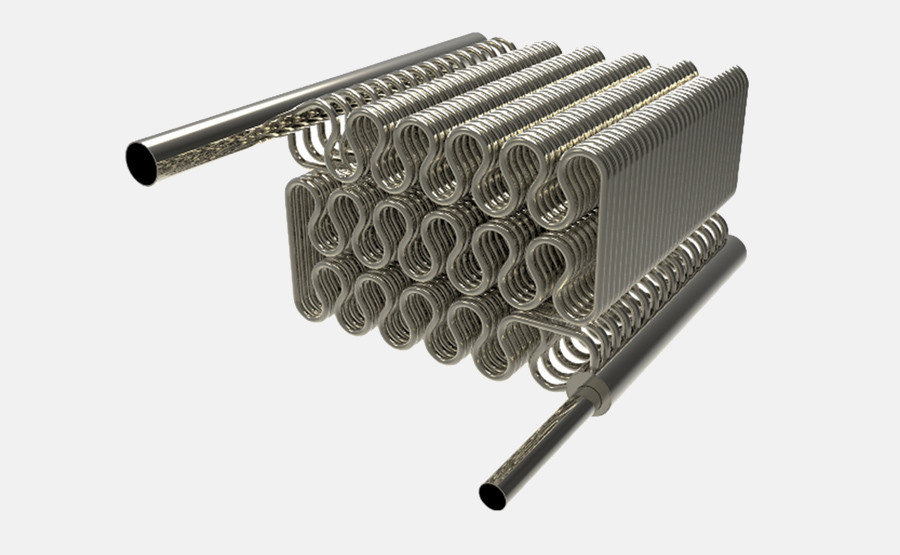

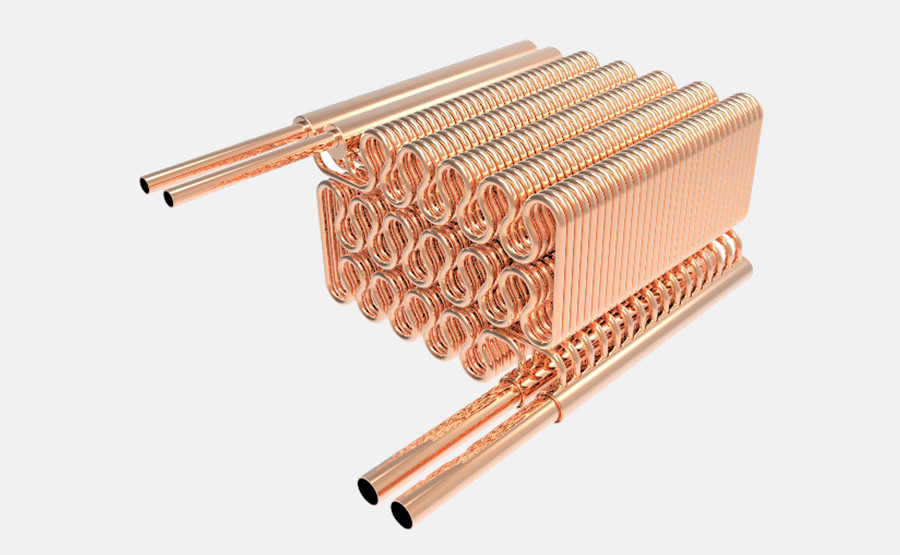

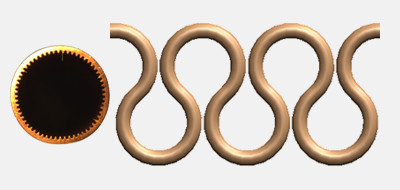

copper inner tube |  cupronickel inner tube |  titanium inner tube |

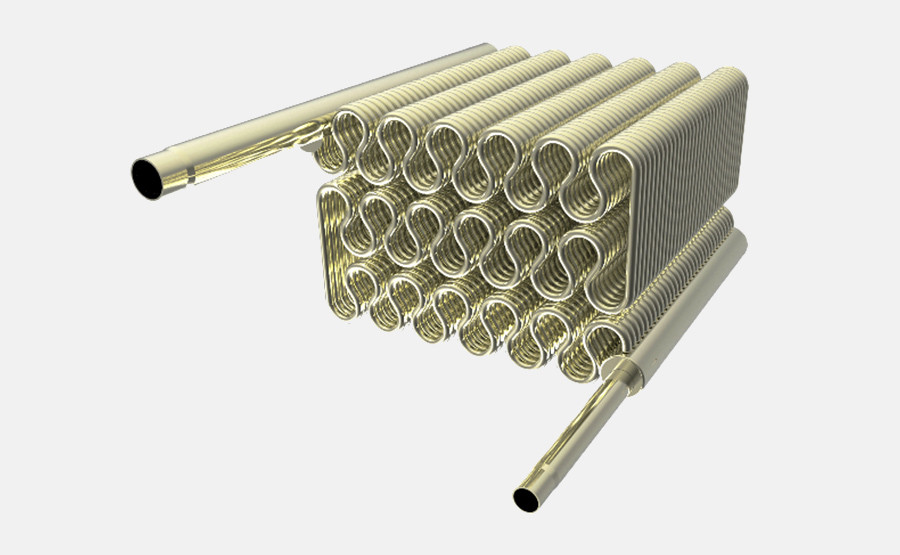

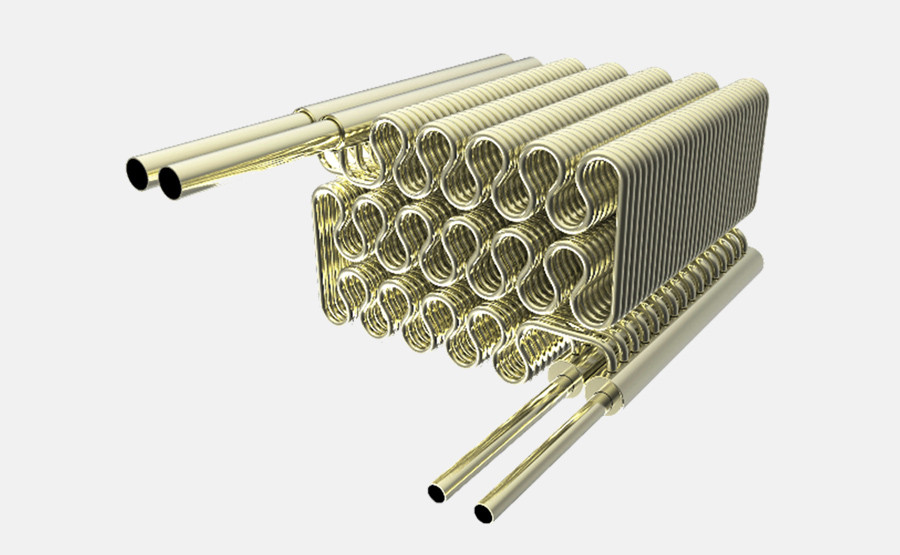

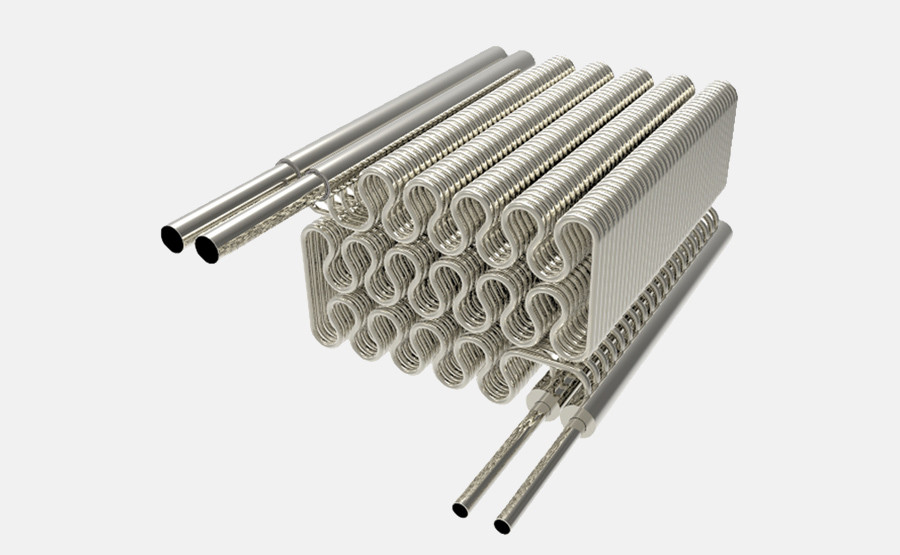

copper inner tube double system |  cupronickel inner tube double sysytem |  titanium inner tube double system |

① Anti-freezingHeat exchanging inner core has a structure of Ω, baffle plate all have the ability of elasticity, so it can anti-freezing. | ② Anti-corrosion, long serve lifeAll surface connect with the water is made by plastic, so it has a better ability of anticorrosion, and can serve for a long time. What’s more the passage of water is large, and not easy to get blocked. |

③ High efficiencyInner pipe is small diameter high efficiency internal thread, and it has a special Ω structure, it can increasing turbulence flow and heat exchanging. HZSS engineers have been simulating and optimization for many times, it is compact and has good performance of heat transfer. |  |

④ Refrigerant outlet and inlet is specially sealed, no leakageSealing components can resistant temperature from 200℃ to -20℃,and sealing covers are used for fixing, which makes the sealing reliable. | ⑤ Filling with heat insulation material, decline heat leakageThe steel shell and the engineering plastic inner bladder are filled with foaming materials, which effectively reduce the heat loss of the heat exchanger. The user does not need to add insulation for the shell. |