The connection between PCHE and FLNG?

The connection between PCHE and FLNG?

With its compact, efficient, reliable, high heat transfer area density, high pressure resistance and low temperature resistance, printed circuit heat exchangers meet the needs of main low temperature heat exchangers for offshore floating natural gas liquefaction. The first choice for the main cryogenic heat exchanger for floating natural gas liquefaction.

PCHE's processing technology mainly uses diffusion bonding, which has high heat transfer area density, high compactness and high heat exchange efficiency; extremely high pressure resistance (maximum pressure resistance up to 60MPa), and high and low temperature resistance (-196 ℃ to 900 ℃). Less leakage and high bonding strength; under the same thermal load, its volume and weight are only about 1/6 of the traditional shell & tube heat exchanger.

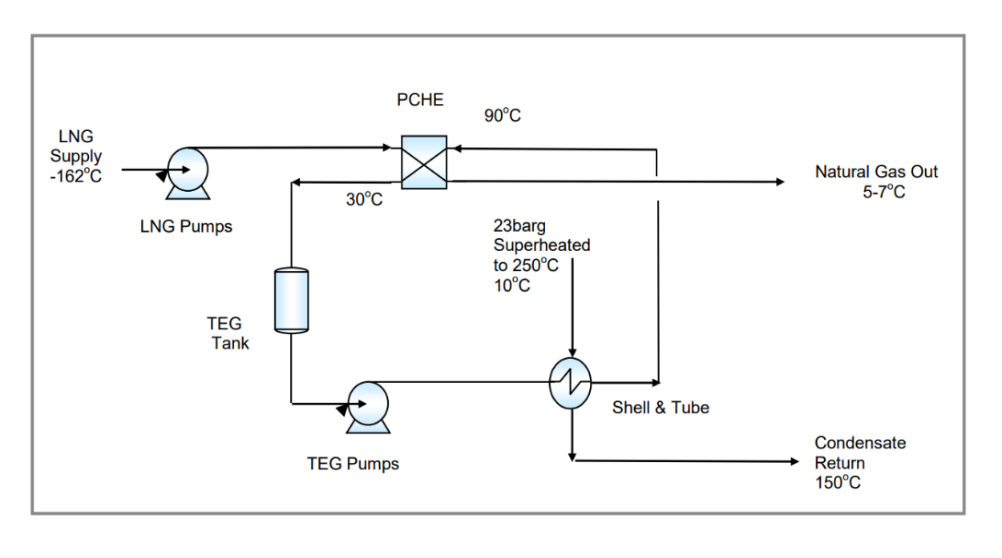

PCHE can be widely used in floating liquefied natural gas production storage and offloading device (FLNG); offshore natural gas liquefaction condenser, regenerator, natural gas regasification evaporator, gas-gas heat exchanger , supercooler, etc. As well as other ocean platforms, floating storage and regasification devices.