Home / Diffusion bonded plate fin heat exchanger (FPHE)

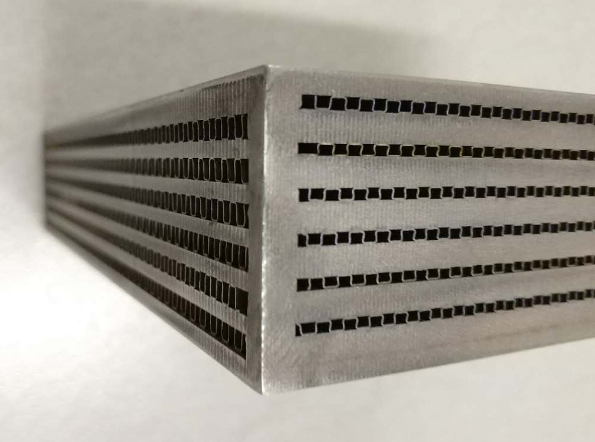

FPHEs, are suitable for gas-liquid and gas-gas heat transfer. Compared with brazed plate-fin heat exchangers, they are solder-free and have strong corrosion resistance (chlorine, acid, alkali, ammonia, Mercury, etc.), high and low temperature resistance (-200 ~ 900 ° C), high pressure resistance (4-15MPa), low leakage rate (1 * 10-9Pa · m3 / s), wide range of materials (titanium, stainless steel, nickel copper, etc ). At the same time, the secondary bonding does not have any effect on the core of the diffusion welding.

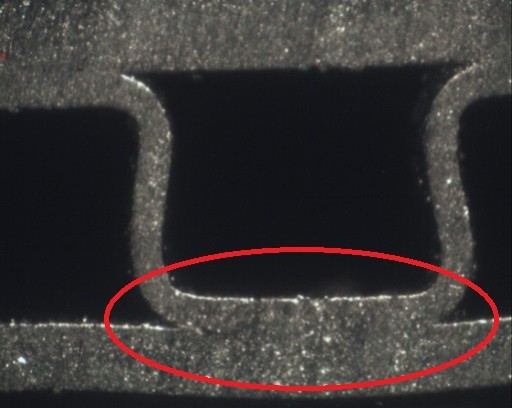

Vacuum diffusion bonding process: in a vacuum environment, the weldment is closely attached, and maintained at a certain temperature and pressure for a period of time, so that the atoms between the contact surfaces diffuse to form a connected bonding method.

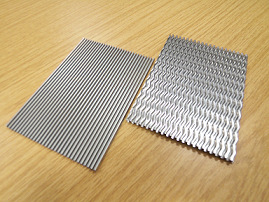

Formed fins |  FPHE |  FPHE |

Wide range of materials: titanium, stainless steel, nickel copper, etc.

Strong corrosion resistance (chlorine, acid, alkali, ammonia, Mercury, etc.), Temperature resistance (-200 ~ 900 ° C), Pressure resistance (4-15MPa), Low leakage rate (1 * 10-9Pa · m3 / s), Wide range of materials (titanium, stainless steel, nickel copper, etc ).

Brayton cycle regenerator and cooler, low temperature field and hydrogen liquefaction system, intercooler for marine gas turbine, vaporizer and liquefied gas for LNG field, etc.