What are the main factors affecting the operation of the heat exchanger?

What are the main factors affecting the operation of the heat exchanger?

Whatare the main factors affecting the operation of the heat exchanger?

Since the emergence of heat exchangers inthe 20th century, heat exchangers have a history of nearly

100 years. The formsof heat exchangers are becoming more and more abundant. Heat exchangers are

used in factories, hotels, restaurants, officebuildings, and entertainment venues. The entertainment venues

have been widelyused.

Figure 1 Chiller

Heat exchangers are used in the industrialfield. In the industrial water consumption, cooling water

accounts for morethan 60% of the total water. However, the cooling water in the circulatingsystem, due to

the increase in water temperature, the change of water flowspeed, and the evaporation of water, Concen-

tration of inorganic ions andorganic substances, cooling towers and pools exposed to sunlight, wind and

rain, dust and debris, as well as equipment structure and materials, etc., areprone to a large number of

microorganisms. Equipment corrosion and deposits, aswell as the resulting slime, dirt and other problems

that block pipelines, evenshut down equipment and cause economic losses.

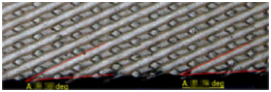

Figure 2 Blocked pipe

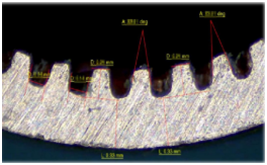

Figure 3 Scaling on theinner wall of the pipe

Figure 4 Scaling on theouter wall of the pipeline

According to observation and research, morethan 90% of ordinary shell and tube heat exchangers have

varying degrees ofscaling problems. From the heat transfer rate equation Q=KS△tm, it can be seen that the

main factors that affect the heattransfer effect of the heat exchanger are: heat transfer coefficient K, heat

transfer area S and average temperature difference △t.The heat transfer area S decreases, which causes the

heat transfer performanceto deteriorate, and the heat transfer efficiency decreases. The averagedecrease

rate can reach more than 30%. In addition to directly causing energyloss, it will also lead to a reduction in

the operating load of productionequipment and affect production capacity. In addition, equipment foul-

ing willalso increase fluid flow resistance, which will increase equipment powerconsumption and periodic

cleaning, which also increases equipment operatingcosts.

After the heat exchanger is fouled, itsthermal resistance increases significantly. At this time, the flow of

therefrigerant (or heating medium) remains unchanged, and the fluid is not easy totransfer the cold (or

heat) to the working fluid side to be exchanged, and itsheat exchange efficiency will be Significantly wor-

se. In this situation, if theprocess still requires the original exchange efficiency to be maintained, it is neces-

sary to increase the inlet water pressure while increasing the flow rateinto the heat exchanger, which

results in a double increase in energyconsumption.

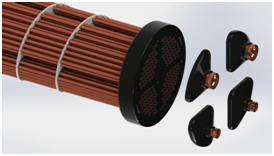

Obviously, this requires very highdescaling ability of the heat exchanger equipment itself. Take the new

generation of shell and tube heat exchangers developed by Hangzhou Shenshi Energy Saving Technolo-

gy Co. Ltd.Shenshi's 130KW shell and tube heat exchanger is usedfor evaporators and condensers of

hot and cold water units, modular units andother units; 7mm heat transfer tube upgrade, spiral baffle

optimization, andmultiple Shenshi's patented distributors are used in combination, It can effectively

improve the descaling ability of theheat exchanger itself, thereby improving the heat exchange efficiency

of theheat exchanger.

Figure 5 Shen's 130KW shell and tubeheat exchanger

Figure 6 Inner tube wall

Figure 7 Shenshi'spatented design-distributor

Hangzhou Shenshi's newgeneration of shell and tube heat exchangers have good performance, safe

use,long service life, small size and high cost performance. They are widely usedin micro-channel heat

exchanger formicro water chiller.