Principle of refrigeration equipment

Principle of refrigeration equipment

Freezing: the operation of using the low temperature source generated by refrigeration to cool the product from room temperature and then freeze it.

Refrigeration: The operation of obtaining a low temperature source by means of a cooling effect resulting from a change in the physical state of the refrigerant.

Types of refrigeration equipment: cold source production (refrigeration), material freezing, cooling.

Refrigeration mode: piston type, screw type, centrifugal refrigeration compressor unit, absorption refrigeration unit, steam injection refrigeration unit and liquid nitrogen.

Freezing mode: air cooled, impregnated and refrigerant through metal pipe, wall and material contact heat transfer and cooling device.

Application:

1. Freezing, refrigerating and freezing transportation of food.

2. Cooling, cold storage, air-conditioned storage and cooling transportation of agricultural products and food.

3. Food processing, such as freezing drying, freezing concentration and material cooling, etc.

4. Air conditioning in food processing plants.

Principle of refrigeration cycle

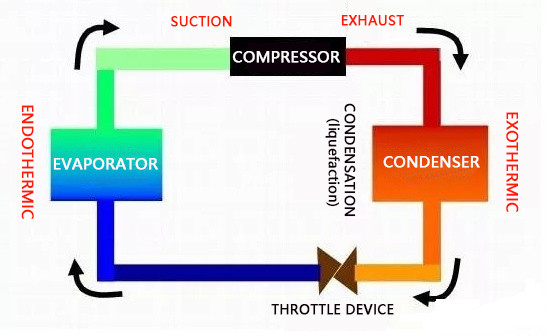

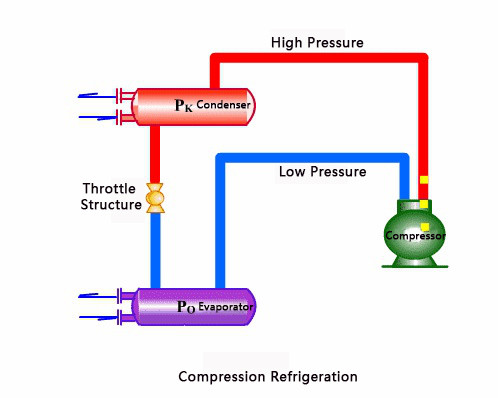

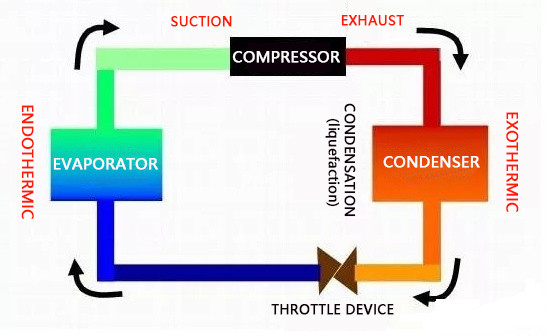

Main devices: refrigeration compressor, condenser, expansion valve, evaporator.

Refrigeration cycle principle: refrigerant in the low temperature low pressure liquid state when heat boiling evaporation become after low temperature low pressure steam, evaporated into gas refrigerants in the compressor, become the high temperature and high pressure gas, after the high temperature and high pressure condensate as high pressure liquid, high pressure liquid after expansion valve into low pressure low temperature, heat evaporation constitutes the refrigeration cycle of refrigerating machine again.

Basic concepts and principles

Refrigeration capacity: under a certain operating conditions (i.e., a certain refrigerant evaporation temperature, condensation temperature, supercooling temperature), unit time refrigerant from the refrigerant removed heat. Also called refrigerant capacity. Under the same conditions, the refrigeration capacity of the same refrigerant is related to the size, speed and efficiency of the compressor.

Direct refrigeration: in the refrigeration cycle, if the refrigerant-absorbing evaporator directly exchanges heat with the cooled object or the surrounding environment of the cooled object. It is generally used in single refrigerating equipment, such as ice cream freezing machine, small refrigerators and household refrigerators.

Refrigerant: A working substance in a refrigeration unit that circulates continuously for refrigeration. The steam compression refrigeration device transfers heat through the change of refrigerant state. Refrigerant is an indispensable substance to realize artificial refrigeration.

Indirect refrigeration: the use of cheap material as a medium to realize the heat exchange between the refrigeration unit and the cold consuming place or machine.

Refrigerant: the refrigerant in the refrigeration device into the evaporator generated by the cold transfer to the cooled object, absorbed heat to the refrigeration device and then transferred to the refrigerant, its own re-cooling cycle.

Principle of indirect evaporative refrigeration

Indirect refrigeration principle: the refrigerant in the evaporator from the refrigerant to absorb cold, through the salt pump into the cold storage, and the cooling object or the medium of the workplace heat exchange absorb heat, back to the evaporator, the absorbed heat transfer to the refrigerant, its own cooling cycle.

Commonly used refrigerant carrier

Commonly used coolant: air, water, brine and organic water solution.

Selection criteria: low freezing point, large specific heat capacity, no metal corrosion, chemical stability, low price and easy access to other factors, as a food industry for the coolant, often must have tasteless, odorless, colorless and non-toxic conditions.

Although air as a load coolant has more advantages, only because of its small specific heat capacity, and as a gas to use its convective heat transfer effect is poor, so in food refrigeration or frozen processing, is used in the form of direct contact with food.

Water is larger than heat, but its freezing point is high, so it can only be used as a refrigerant for making a cooling capacity above 0℃. If you want to make the coolant below 0℃, use brine or organic solution as coolant.

The aqueous solution of sodium chloride, calcium chloride and magnesium chloride is usually called frozen brine. The most widely used frozen brine in the food industry is sodium chloride aqueous solution. Among the organic solution coolers, the two most representative coolers are the aqueous solution of ethylene glycol and propylene glycol.

(Not the original)