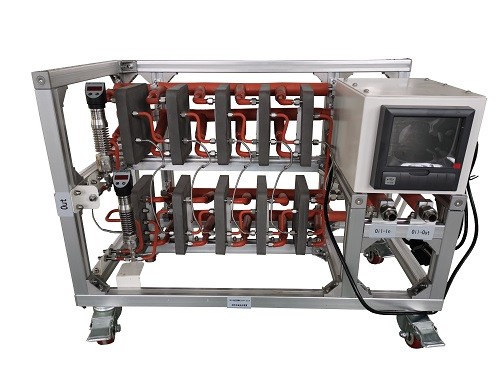

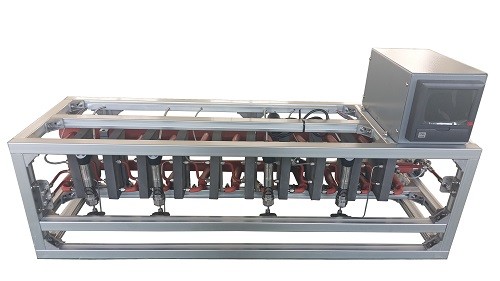

Microchannel heat exchanger for microreactor

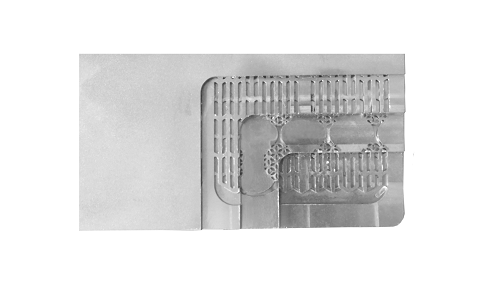

The microchannel heat exchanger has the advantages of high heat transfer characteristics, small channel size, and channel diversity. It also has the characteristics of quickly dispersing the fluid medium into a very small fluid unit, which is suitable for integration in large-scale reactor units.

Application

Micro-channel heat exchangers are used in micro-reactors and are suitable for chemical, pharmaceutical, and dye fields; and have been increasingly used in the synthesis of pharmaceuticals, pesticides, special materials, and fine chemical products and intermediates.