New condition Shell & tube heat exchanger

| Categories | Shell and tube heat exchanger |

|---|---|

| Brand | SS coaxial coils |

| Model | SS-KG168-R-2-C |

| material | stainless steel |

| condition | new |

| warranty | more than 1 years |

| FOB port | Shanghai/Ningbo/Guangzhou |

| Terms of Payment | L/C |

| Update Time | Jul 27,2024 |

Product Introduction

Shenshi's 65 & 130KW shell and tube are used for evaporators and condensers of hot and cold water units, modular units and other units. 7mm heat transfer tube upgrade, spiral baffle optimization, and multiple Shenshi's patented distributors are used in combination, with high heat exchange efficiency ; Shenshi's shell tube is designed and manufactured strictly in accordance with GB150, 151 standards. The fluorine side head is laser welded, with high pressure, no risk of leakage from traditional gaskets, the heat exchange tube is integrally formed, no splicing, no solder joints and water Contact, freeze resistance and strong reliability; Patented optimized design of the fluorine side head saves material costs, small hosing for small heat transfer tubes, high compactness, and small material consumption.

Product Features

1. High heat exchange efficiency

2. 7mm heat transfer tube

3. Spiral baffle

4. Patent dispenser

5. Laser welding for more sealing

6. Integrated molding without splicing

7. Strong frost resistance

8. Excellent value for money

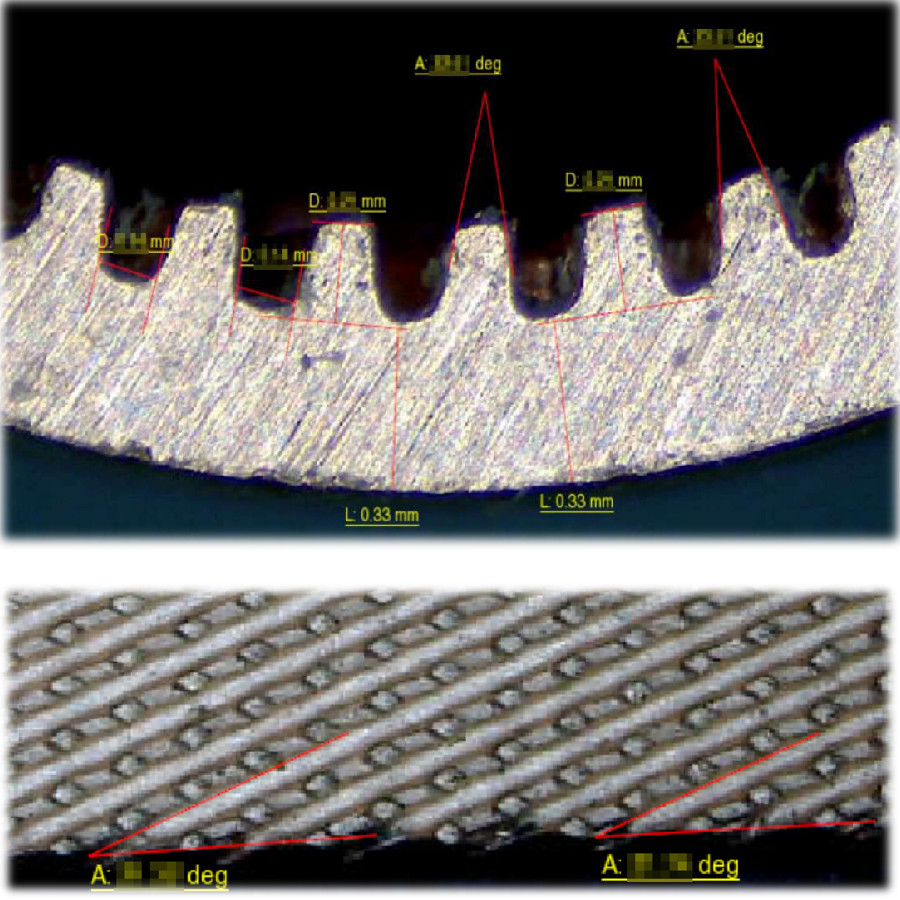

Heat Transfer Tube

7mm heat transfer tube, bottom wall thickness 0.35mm, number of teeth, tooth height and helix angle are all own parameters, the result of repeated optimization.

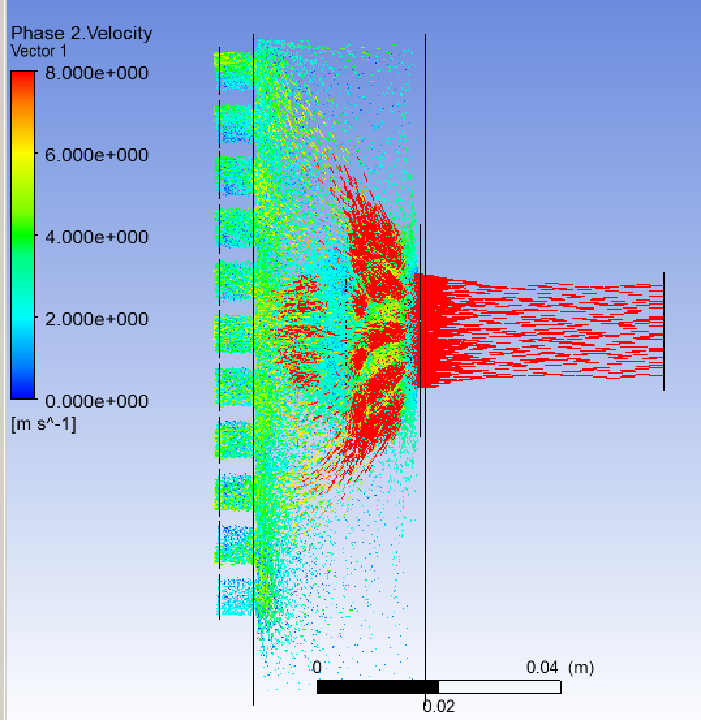

Patent Distributor

Refrigeration: 1 mix + 2 distributions Heat pump: 1 mix + 1 distribution

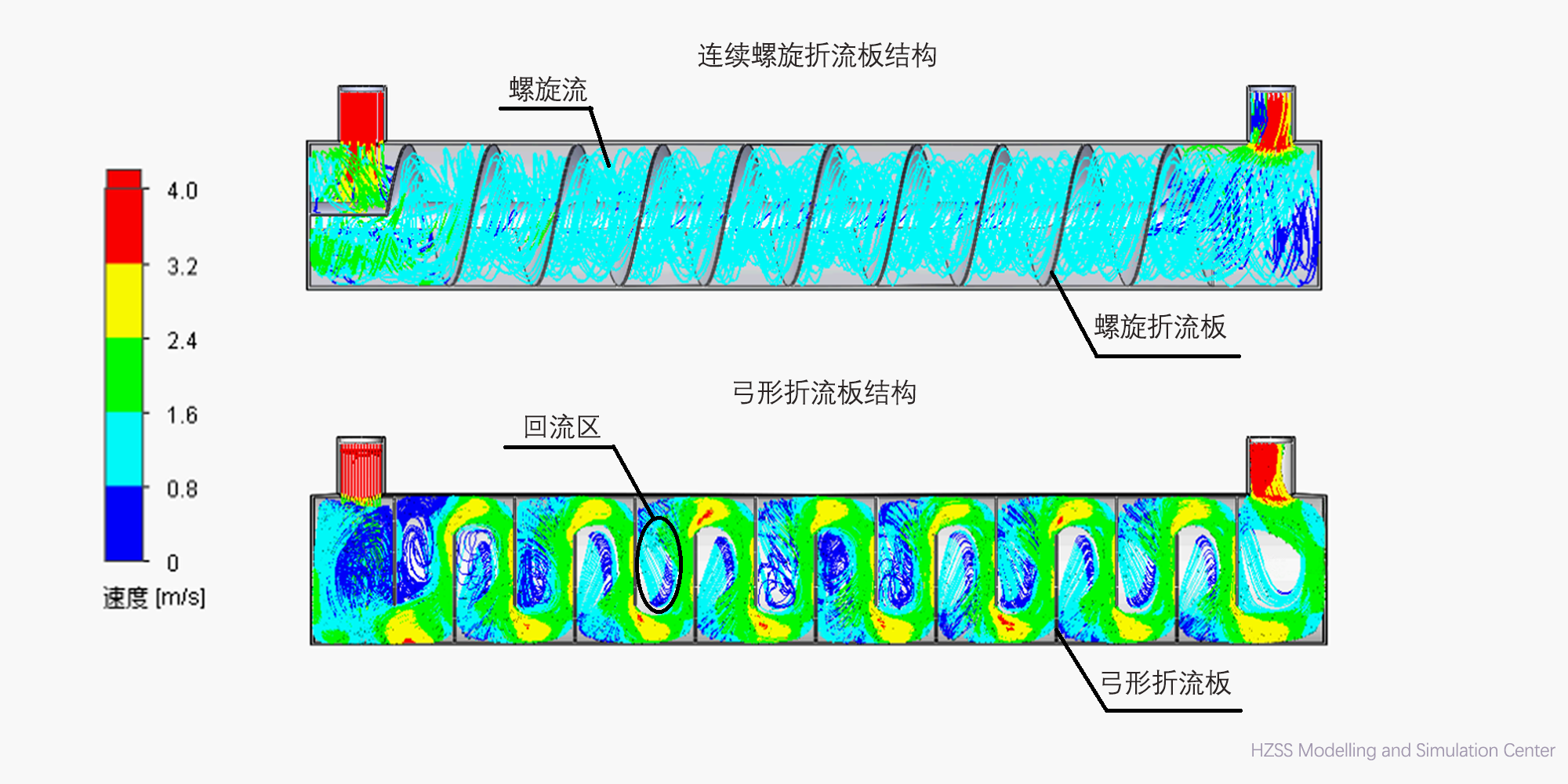

Spiral Baffle

unique lock design, tight stitching in the splicing area, smooth and natural transition, uniform flow velocity on the water side, high heat exchange efficiency; no dead zone, reducing freezing risks.

Laser cutting process Inner tube bending process Robot Expander

Laser welding of fluorine side head Four-axis machining center Laser welding of fluorine side head

|

SIZE

|

||||||

|

Model |

WindpipeID (mm) |

Liquid pipeID (mm) |

Nozzle size | Length (mm) | Width (mm) |

height (mm) |

SS-KG168-R-2-C | 28.6 | 16 | DN65 | 1735 | 375 | 483 |

SS-KG168-B-2-C | 28.6 | 16 | DN65 | 1735 | 375 | 483 |

SS-KG168-G-2-C | 28.6 | 16 | DN65 | 1735 | 375 | 483 |

SS-KG219-R-2-C | 35 | 22 | DN65 | 1772 | 470 | 498 |

SS-KG219-R-4-C | 28.6 | 16 | DN65 | 1768 | 470 | 498 |

SS-KG219-B-2-C | 35 | 22 | DN65 | 1772 | 470 | 498 |

|

SS-KG219-B-4-C |

28.6 |

16 |

DN65 | 1768 | 470 |

498 |

|

SS-KG219-G-2-C |

35 |

22 |

DN65 | 1772 | 470 |

498 |

2019 AHR in Atlanta

2018 Germany Refrigeration Exhibition

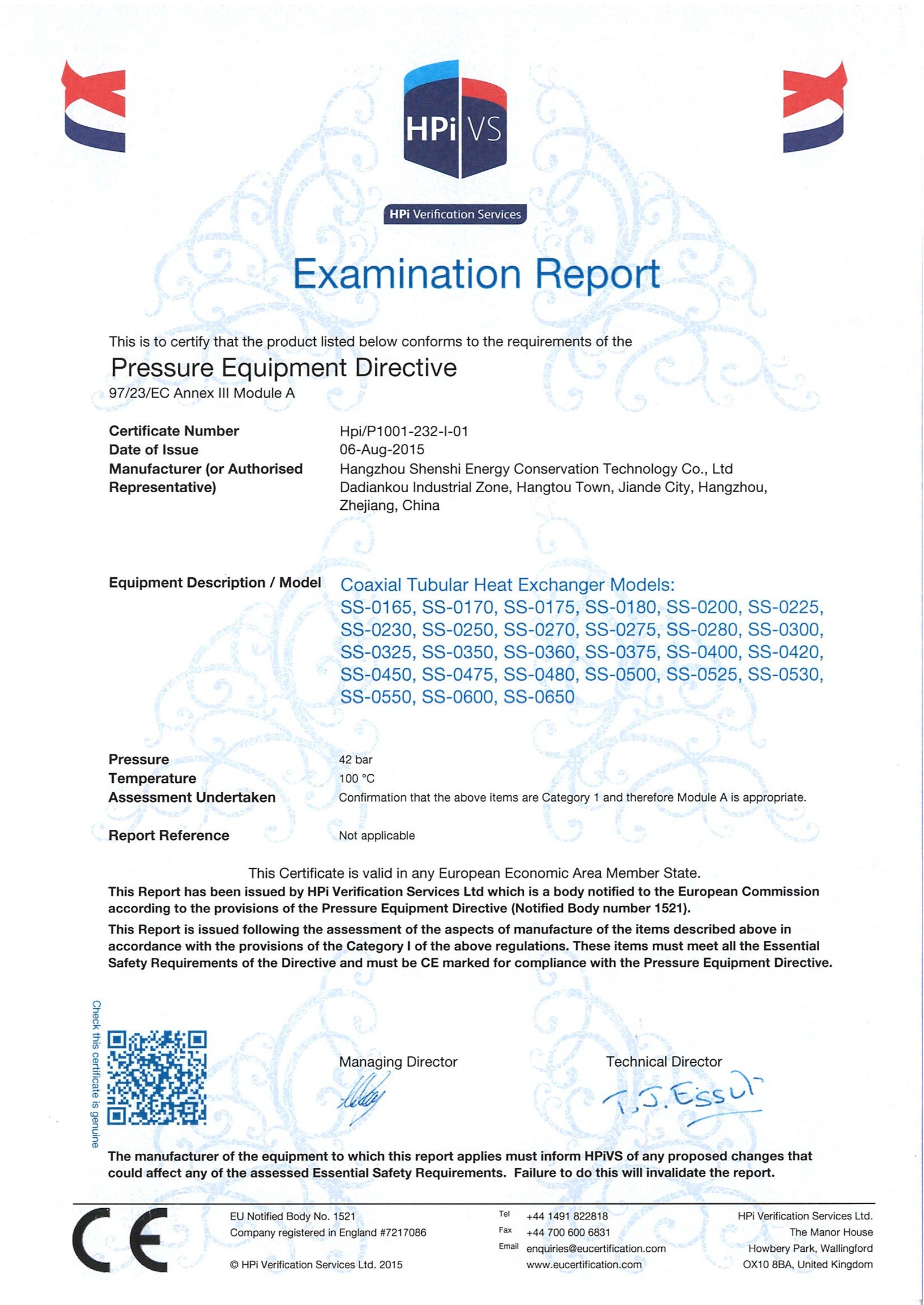

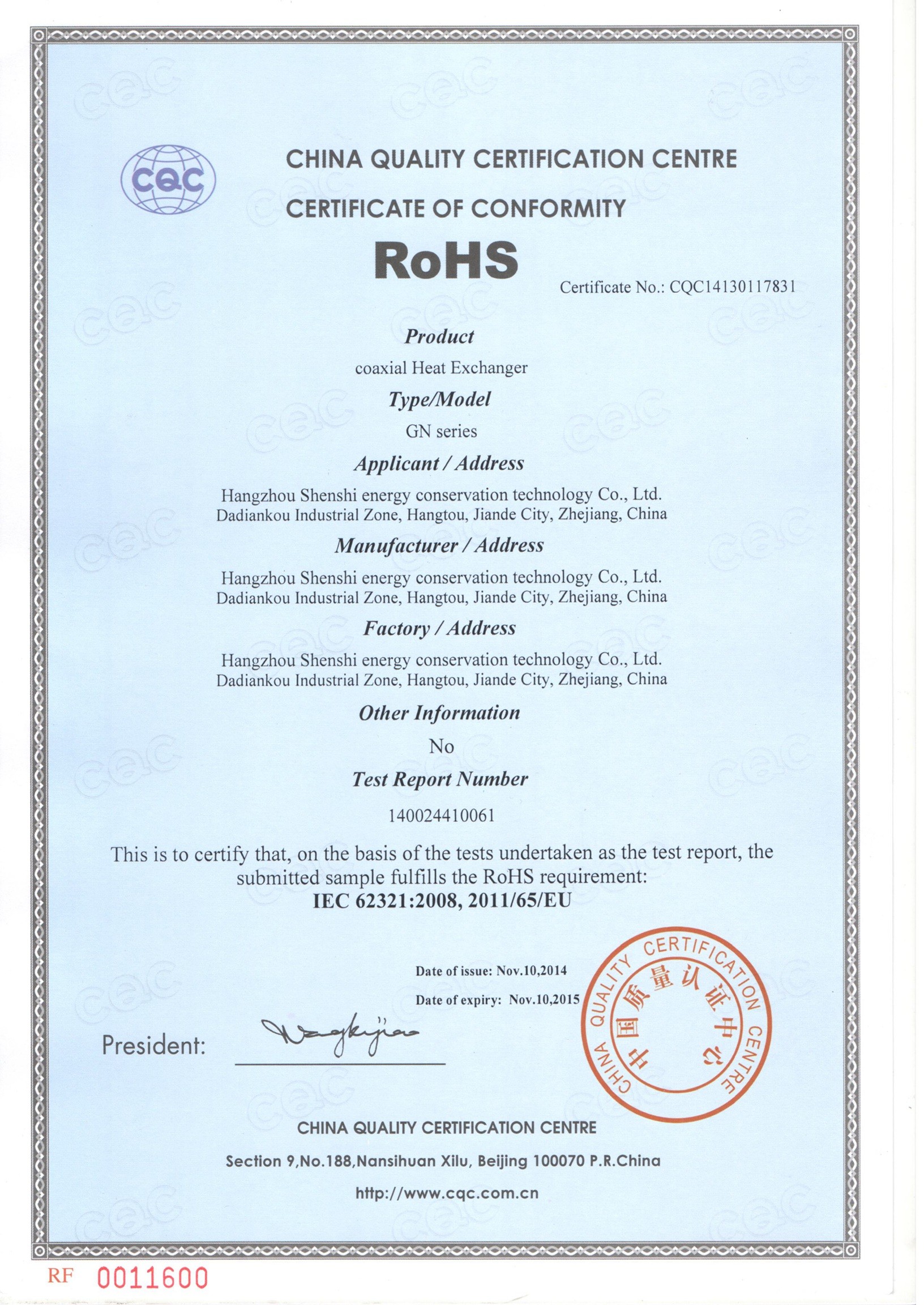

Hangzhou Shenshi Energy Conservation Technology Co.,Ltd was set up in the year of 2005(the original name was Hangzhou Shenshi Heat Exchanger Co.,Ltd),located in Hangzhou Jiande, Zhejiang Province , China.HZSS is one of the largest coaxial heat exchanger manufacturers and the inventor and standard maker of shell pipe heat exchanger,and owns the global-leading technology of integrated micro-channel heat exchanger and small climate system.HZSS production and marketing of high effciency and energy saving heat exchangers.

1.Carton packing: only for small size,light weight products.

1.How to choose a match heat exchanger?

- Name

- Tel

- *Title

- *Content